OUR SERVICES

Professional vehicle repairs, diagnostics and MOT services in Purfleet.

Serving Purfleet, Thurrock, South Ockendon, Dartford and surrounding areas across Essex and Kent.

MECHANICAL REPAIR & MAITENANCE

Engine Servicing & Maintenance

Regular interim, full and major servicing to maintain reliability, fuel economy, and a strong service history. Includes oil, filters, inspections, and service resets where applicable.

Clutch & Flywheel Systems

Clutch and flywheel replacement (including dual mass flywheels) to fix slipping, vibration and poor engagement. Includes hydraulic checks to prevent repeat failures.

Braking Systems

Complete brake servicing and repairs including pads, discs, calipers, sensors and brake fluid. Focused on safe stopping, reduced brake noise, and even brake wear.

Heating Systems

Heating and climate control repairs to restore cabin comfort and clear windows quickly. Covers blowers, heater matrices and coolant flow issues.

Timing Belts, Wet Belts & Timing Chains

Timing belt (cambelt), wet belt and timing chain replacement including tensioners, guides and all related components. This service prevents major engine damage, timing rattle or noise issues, and sudden timing failure. Water pumps are replaced where applicable to ensure long-term reliability and reduce the risk of repeat labour.

Turbochargers & Wastegate Systems

Turbo and boost system diagnosis for low power, smoke, limp mode and boost leaks. Repairs include turbo units, actuators, intercoolers and boost pipework.

Cooling System Repairs

Cooling system diagnosis and repair for overheating, coolant loss and heater issues. Covers radiators, thermostats, pumps, hoses, fans and pressure testing.

Alternators & Starter Motors

Starter and alternator testing and replacement to resolve slow cranking, charging warnings and intermittent starting. Includes wiring and battery checks for accurate diagnosis.

Camshaft Repairs

Camshaft and valvetrain fault diagnosis, repair or replacement to restore power, smooth running and correct valve timing. Ideal for ticking noises, misfires, and wear-related performance loss.

Steering Systems

Steering repairs for play, knocks and uneven tyre wear, including racks, pumps and linkages. Restores safe handling and correct road feel.

Exhaust & Emissions Systems

Exhaust and emissions repairs to improve performance and MOT compliance, including DPF, EGR and catalytic converter faults. We diagnose causes to prevent repeat issues.

Water Pump Replacement

Water pump replacement completed together to reduce labour duplication and protect the engine from overheating. Includes coolant refill/bleed and system checks.

Suspension Repairs

Suspension repairs including arms, bushes, shocks and struts to improve ride comfort and stability. Helps prevent uneven tyre wear and poor alignment.

Battery & Charging Systems

Battery testing and charging system diagnosis for non-starts and warning lights. Covers alternators, parasitic drain checks, and replacement where required.

Gearbox Transmission Servicing

Manual and automatic transmission servicing and repairs including fluid changes, filter, sump fans (where applicable) and fault diagnosis. Helps improve shift quality, reduce judder/slip, and extend gearbox life.

Driveshafts & CV Joints

Driveshaft and CV joint repairs to fix clicking on turns, vibration under load and grease leaks. Prevents further drivetrain wear and costly knock-on damage.

Air Conditioning Systems

Air con regas and repair for weak cooling, smells or leaks. Includes pressure checks, leak testing and component replacement if needed.

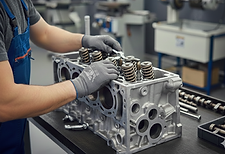

ENGINE REBUILDS & RECONDITIONING

Cylinder Head Reconditioning

Cylinder head repairs including valve replacement, valve seat cutting, pressure testing and resurfacing. Restores compression, combustion efficiency and engine performance.

Engine Block Reconditioning

Engine block cleaning, crack testing, line boring and machining. Provides a solid and reliable foundation for engine rebuilds.

Turbocharger Rebuilds

Complete turbocharger rebuilds including bearing and seal replacement and balancing. Restores boost pressure and engine response.

Oil Consumption Diagnosis

Detailed diagnosis of excessive oil usage caused by rings, valve seals, PCV systems or internal wear. Prevents unnecessary repairs.

Crankshaft Grinding & Balancing

Grinding, polishing and balancing of crankshafts to manufacturer tolerances. Reduces vibration, bearing wear and internal engine noise.

Gaskets & Engine Seals

Replacement of all major engine gaskets and seals to prevent oil and coolant leaks. Includes head gaskets, timing covers and oil seals.

Valve Train Repairs

Replacement or adjustment of valves, springs, retainers and rocker arms. Ensures efficient engine breathing and combustion.

Exchange & Reconditioned Engines

Supply and fitting of fully reconditioned or exchange engines as a cost-effective alternative to rebuilds. Suitable for a wide range of vehicles.

Pistons & Piston Rings

Replacement of pistons and piston rings to restore compression and reduce oil consumption. Resolves blue smoke, power loss and excessive oil usage.

Camshaft & Timing Reconditioning

Inspection and reconditioning of camshafts, timing chains, gears and guides. Restores correct valve timing and smooth engine operation.

Engine Mount Replacement

Replacement of worn engine mounts to reduce vibration and improve drivetrain alignment. Enhances comfort and protects transmission components.

Cylinder Bore Honing & Resleeving

Cylinder bore honing or re-sleeving to correct scoring and wear. Restores proper piston clearance and sealing.

Oil Pump Repairs

Inspection, servicing or replacement of oil pumps to maintain correct oil pressure. Protects internal engine components from wear and failure.

Full Engine Assembly & Testing

Precision engine assembly followed by compression testing, oil pressure checks and leak inspection. Ensures reliability before installation.

Main & Big End Bearings

Replacement of worn crankshaft bearings to prevent knocking noises and internal engine failure. Essential during major rebuilds.

Injector Testing & Reconditioning

Injector cleaning, testing and refurbishment to restore accurate fuel delivery. Improves performance, smooth running and emissions.

Post-Rebuild Testing & Run-In

Controlled engine run-in procedure to allow components to bed in correctly. Includes final inspection and performance checks.

MOT: PRE-MOT CHECK & MOT TESTS

Comprehensive Pre-MOT Inspection

A full inspection of safety-critical and emissions-related components commonly assessed during MOT testing. Identifies potential failure points in advance to avoid unexpected MOT failures.

Suspension & Steering Checks

Inspection of suspension and steering components for wear, play or damage that could result in MOT failure or advisory notices.

Emission System Testing

Pre-MOT emissions checks on diesel and petrol vehicles, including DPFs, catalytic converters and exhaust systems. Helps reduce the risk of MOT emission-related failures.

Fluid Level & Leak Checks

Inspection and top-up of essential fluids including engine oil, coolant and brake fluid. Includes checks for visible leaks that may affect MOT results.

Tyre Condition & Pressure Checks

Inspection of tyre tread depth, sidewall condition and pressures to ensure legal compliance, road safety and MOT readiness.

MOT Test

On-site MOT testing carried out in line with DVSA requirements for all makes and models. Includes verification of required documentation and clear communication of results.

Brake System Inspection

IInspection of brake pads, discs, calipers and brake fluid condition to confirm effective braking performance and MOT compliance.

Pre-MOT Repairs

Rectification of faults identified during pre-MOT inspections to maximise the chance of a first-time MOT pass.

Lighting & Visibility Checks

Inspection of all exterior lights, indicators, brake lights, number plate lights and windscreen wipers. Addresses one of the most common MOT failure areas.

MOT Failure Repairs

Targeted repairs following MOT failure reports to return the vehicle to a road-legal standard and achieve a pass.

DIAGNOSTICS, SCAN-TESTS & ELECTRICAL REPAIRS

Diagnostic Scan Testing

Full vehicle diagnostic of all vehicle modules including scanning of engine, gearbox, ABS, airbag and body control systems using professional equipment.

ECU Programming & Calibration

ECU coding, software updates and adaptations to restore correct system operation.

Post-Diagnostic Validation

Final system testing and road testing where required to confirm faults have been fully resolved.

Fault Code Interpretation

Detailed fault analysis using live data and guided testing to identify root causes rather than symptoms.

CAN-Bus Network Repairs

Diagnostics and repair of vehicle communication network faults affecting multiple systems.

Sensor Testing & Replacement

Testing and replacement of faulty sensors affecting engine performance, emissions and drivability.

Electrical Component Repairs

Repair or replacement of electrical components including alternators, starter motors and comfort systems.

Electrical Fault Finding

Diagnosis and repair of wiring faults, blown fuses, poor connections and parasitic battery drain.

Hybrid & EV Diagnostics

Specialist diagnostics for hybrid and electric vehicles using high-voltage safety procedures.

Battery & Charging Diagnostics

Battery health testing and alternator output checks to resolve starting and charging issues.

Lighting & Indicator Repairs

Diagnostics and repair of interior and exterior lighting faults including LED and halogen systems.

ECU MAPPING & SOFTWARE SOLUTIONS

Stage 1 ECU Mapping

Software optimisation for standard vehicles to improve power, torque and drivability within safe limits.

Stage 2 ECU Mapping

Custom mapping for vehicles with supporting hardware upgrades to achieve enhanced performance.

Economy ECU Mapping

Fuel-efficiency-focused mapping to improve MPG and smoother throttle response for everyday driving.

DPF, EGR, NOX & AdBlue Software Solutions

Software-based solutions for recurring emissions system faults where legally permitted, following full diagnostics. This includes ECU programming for track and off-road use (subject to appropriate documentation provided by the customer).

Gearbox ECU Mapping

Transmission software optimisation to improve shift quality and driving comfort where supported.

DIESEL INJECTOR FUEL TESTING & REPLACEMENTS

Diesel Injector Testing (Bosch Equipment)

Specialist diesel injector testing carried out using Bosch injector test equipment to accurately assess injector performance, response and fuel delivery. Provides reliable fault confirmation prior to injector replacement.

Injector Flow & Leak-Off Testing

Detailed flow and leak-off testing to measure injector balance and identify internal leakage. Essential for diagnosing misfires, rough idle, smoke and excessive fuel consumption.

Injector Ultrasonic Cleaning

Ultrasonic cleaning used as a diagnostic support process to remove surface carbon deposits before final testing. Helps confirm injector condition prior to replacement where required.

Injector Replacement

Supply and replacement of faulty diesel injectors following confirmed test results. Ensures correct fuel delivery, smooth engine operation and long-term reliability.

Injector Coding & Calibration

Injector coding and calibration to the ECU following replacement to ensure correct fuel quantities, smooth running and emissions compliance.